Why we need the Internet of Things system

ØIn traditional feed plants, only the central control room can see a little more data, but the central control room is for the purpose of operation, and its limited data is only used to guide the startup and shutdown. The Internet of Things uses increasingly mature sensor and Internet technology, mainly for management and data analysis, to improve efficiency, reduce costs and ensure quality.

ØTraditional management patrols, although you can see the current dripping and leaking, however, it is impossible to fully record the 24-hour startup status of each equipment, draw curves, and analyze and count each status. The Internet of Things can do this very easily,then increase efficiency and reduce cost.

Advantages of the Internet of Things system

Ø Improve equipment efficiency. For the feed factory with the current traditional management mode, the IoT system can effectively avoid overload, underload and no-load.

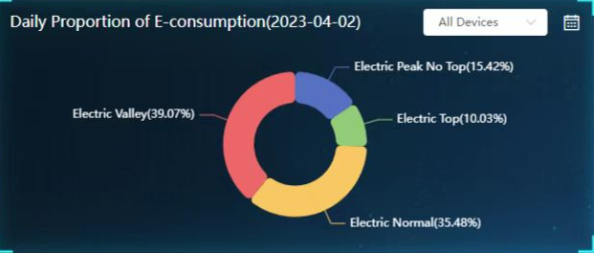

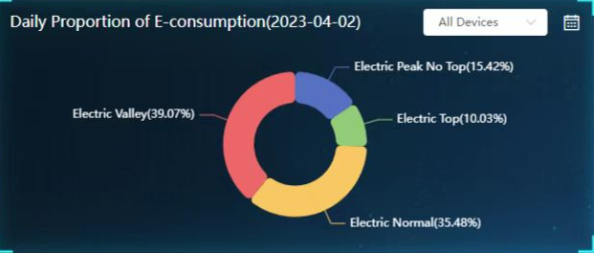

ØReduce power consumption. Visualize the distribution of flat, valley and peak power consumption, which can optimize the startup period to the maximum extent.

ØGuarantee quality.

Ø Avoid unexpected shutdown and prolong the service life of the equipment.

For example:A pig feed company has increased its efficiency by 22.2% by using this tool, from the original daily output of 180 tons per shift to 220 tons. The power consumption per ton decreased from 28 ° C/t to 23 ° C/t, about 18% lower.

Functions of the Internet of Things system

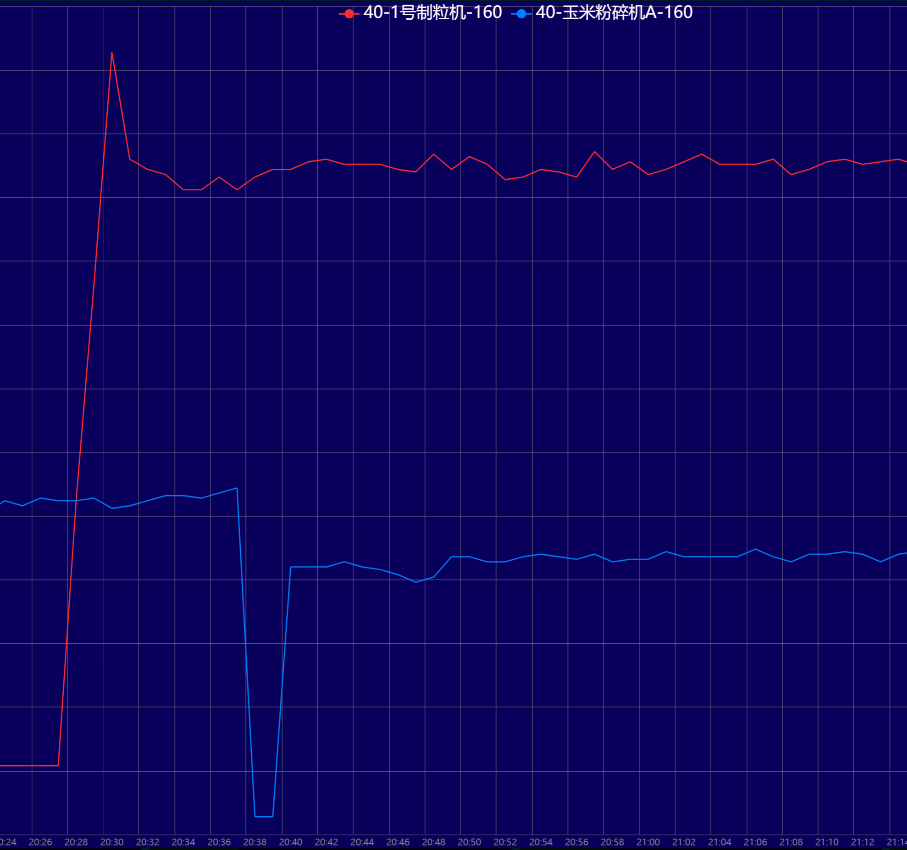

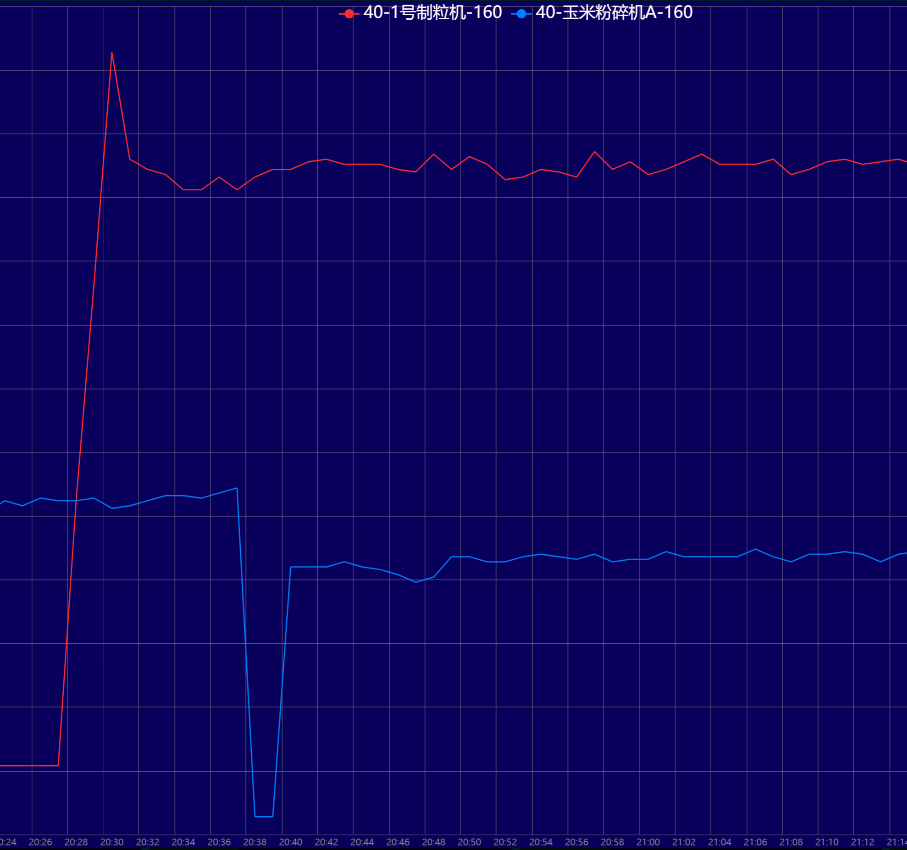

Ø Generate 24-hour curve of each host:

Users can see the real-time status of each host, such as startup, shutdown, overload, underload, and no-load, to improve the equipment efficiency and reduce energy consumption in all aspects;

The collaboration time of each post is visualized, such as the switching time of the central control crushing variety, the switching time of the batching variety, the switching time of the granulating variety, and so on. In order to improve management efficiency, sufficient data has been improved.

Ø Energy consumption analysis

Users can see the peak-valley distribution diagram of the power consumption of the day, the peak-valley distribution diagram of the cumulative energy consumption of the month, and the power consumption statistics of a single shift.

ØEarly warning function

This function includes early warning of equipment operation voltage, whether the motor has turn-to-turn open circuit, no-load timeout, high bearing temperature and so on... The alarm is set on the site, and will enter the system report if it is not handled in time.

Ø Startup rate statistics

Users can see the power-on time chart of the day, the power-on rate and the idle rate of the month; Provide important data on whether each company needs technical transformation.

Ø Main engine maintenance

The preventive equipment maintenance of the system can avoid fire fighting equipment maintenance, which will cause various losses and then maintain the equipment. This module includes daily inspection of the host; Regular inspection; Feedback problems and other functions.

Ø Capacity statistics

The Internet of Things can automatically count the output. Each equipment also has a production registration window, which is then associated with power consumption and startup time to automatically generate tons of power consumption, hourly production, etc.

Ø Historical data storage

Each data can be stored for many years for easy viewing.

Ø Visualization

The system includes TV app, mobile app and computer web page. Visualization makes each post more convenient and efficient.