Auto-Control

clicks:384

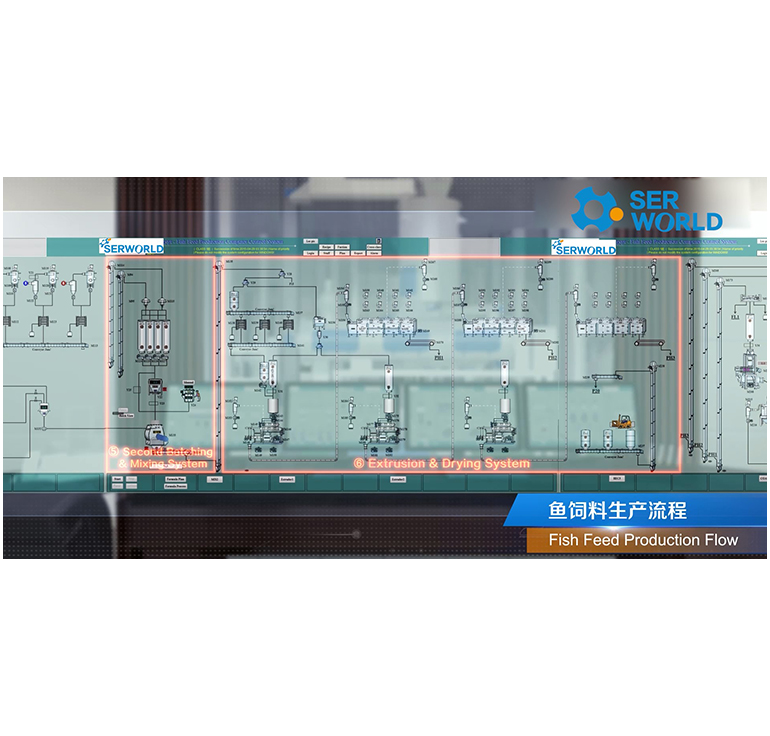

ØAdopting the open distribution control mode, this system consists of the monitoring/controlling machine, (imported industrial computer with CIT configuration software) and PLC with other intelligent equipment, including CC-link network. This link network has the following features:

1. Expandable structure that allows easy expansion and addition of new equipment.

2.On-line replacement of any equipment without the need of stopping the whole system.

3.Fast speed (reaching 10 MB/Second within 100m) and long distance (maximum 1.2 Km).

4.Capable of connecting in and transmission of large amount of distant signals into the central control room through the network, thus reducing the cost of wiring, installation and maintenance.

5.Flexible structure that allows I/O operation, alarming, reports generating, trend analysis and display on one or more servers.

6.Network redundancy.

7.Low cost.