Poultry And Livestock Feed

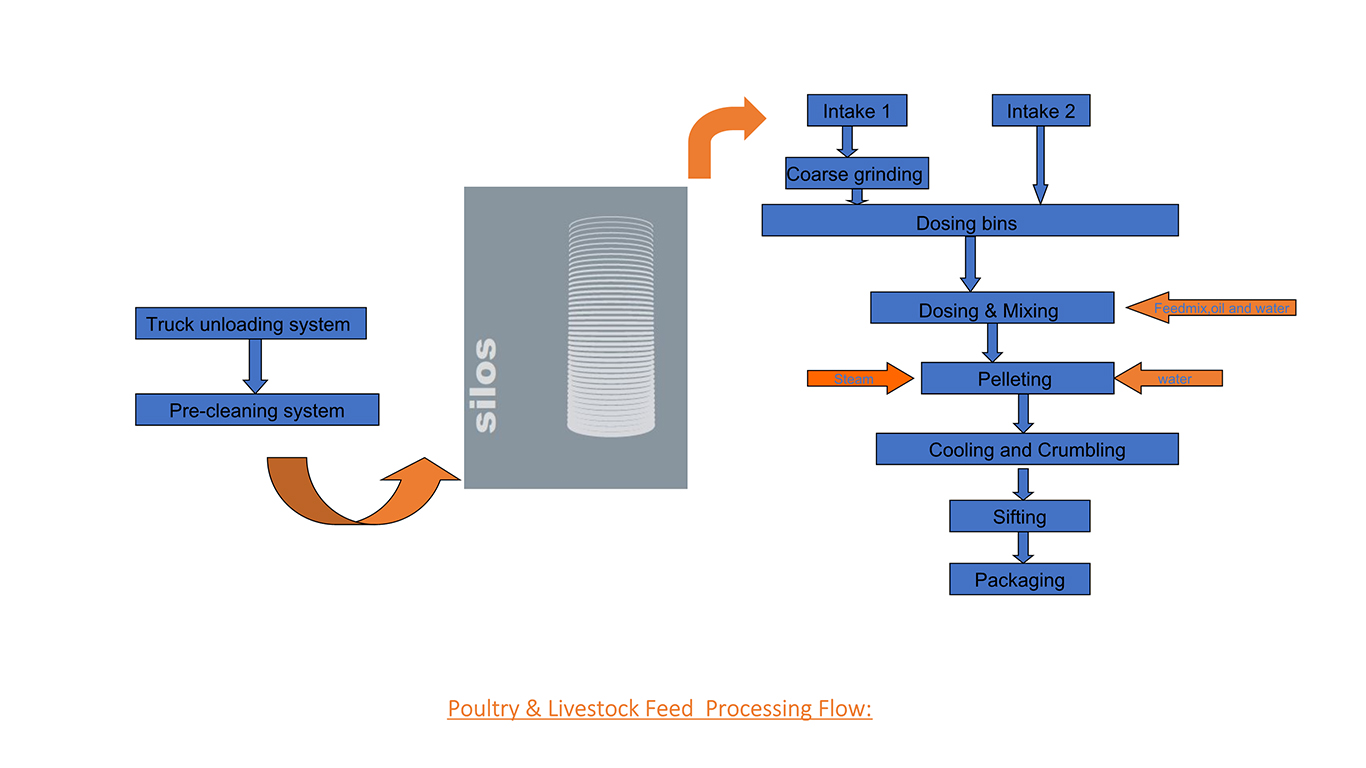

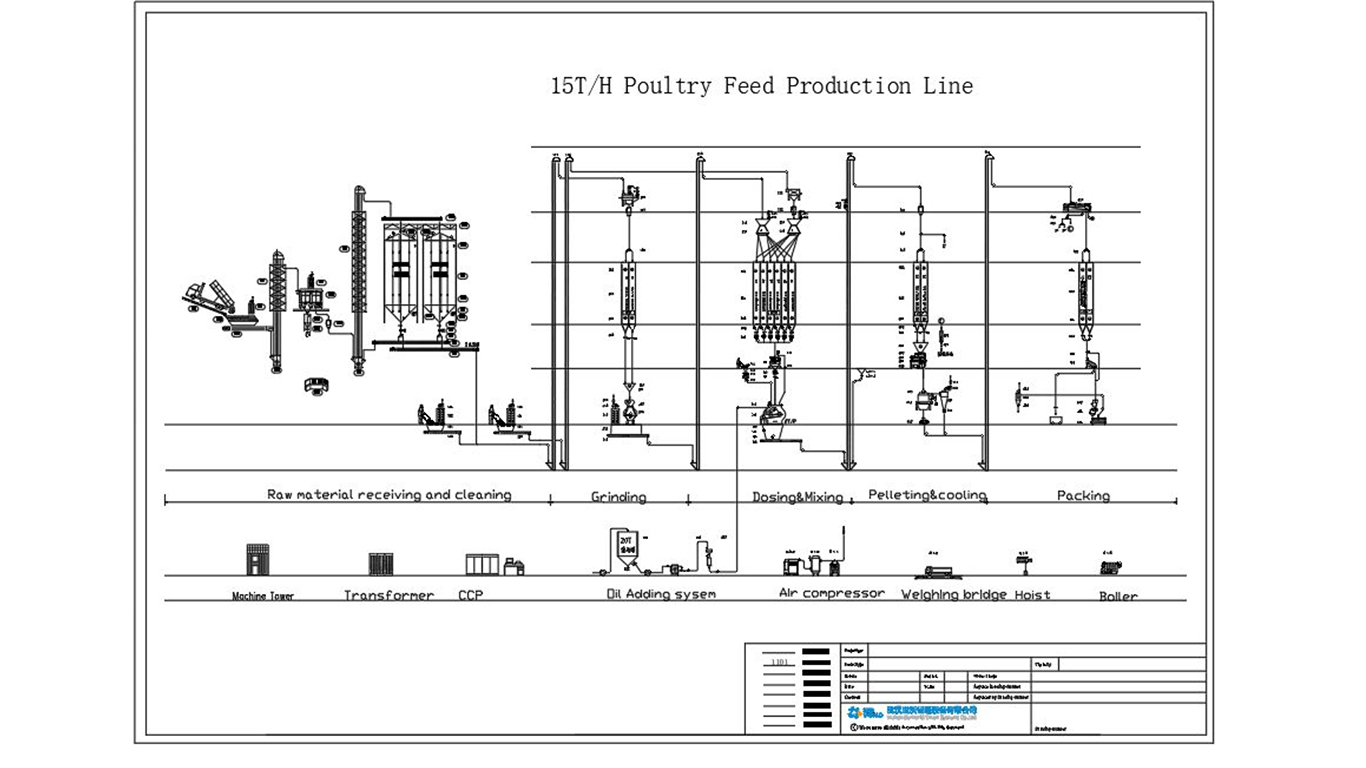

Common livestock and poultry feed including swine feed, chicken feed, duck feed, cattle and sheep feed and other ruminants. The livestock and poultry feed processing process usually includes raw material receiving section, grinding section, ingredients dosing &mixing section, pelleting, crumbling and cooling section, screening and packaging section. During the mixing process, liquid, oil and premix additives will be added. Typical processing flow will show as follow:

Advantages of Pellet Feed:

Easy Digestive :

ØThe combination of moisture, heat and pressure on natural high energy feed produces a degree of gelatinization which enables animals to better utilize the ingredients, thus improving feed conversion ratio.

Appetizing (Good smell) :

ØHeat from pelleting process causes of good smell of pellets and animals will like when they eat, otherwise coating pellets with appetizing substances will be easy to do.

Raw materials in pellets do not segregate :

ØSo each of pellet has regular nutrition hence impossible for the animal to be selective. Can use several of raw materials to produce feed and can change several feed formulation.

Increase density :

ØPelleting process will increase density of pellet causes of easily transportation ,highly quantity of storage, reduced loss when transportation and fed otherwise can controlled the pellet density as required as animals behavior ,thus reducing the remaining feed form eating of animals, such as highly density pellets can submerge with long time and animals can eat all.

Easily flow:

ØPellets will make transportation to be easily, used with automation fed as well.

Good feed hygiene :

ØThe heat of friction occurred by pressing the feed through the die can destroyed most of the common bacteria and fungi.

Core process of poultry and livestock feed:

Advantages of grinding process consist of:

Ø Reduce particle size as required.

ØControl size and shape of raw materials regularly.

Ø Increase surface area of material.

ØGet grinding capacity as required.

Ø Reduce loss from diffusion of raw materials.

Ø Prevent strange matter.

Ø Make customers satisfaction.

Advantages of mixing process consist of:

ØGet raw material proportion as required formula.

ØRegular raw materials proportion in sample.

Ø Homogeneous.

ØRaw material able to absorb adding liquid and do not agglomerate.

ØGet regular quality product within assign time.

ØPrevent strange matter and remainder in meat.

ØRegular physical quality that make customer satisfaction.

Advantages of pelleting consist of:

ØTransform mash raw material to pellet as required size.

Ø Control size, shape and stability of pellet regularly.

ØRaw materials do not segregate so raw materials proportion still regularly.

Ø Increased Specific Weight, Bulk Density and Flow Ability of feed (Suitable to consuming behavior for each animal).

Ø Reduce loss when fed.

Ø Raw materials ripened (Easy digestive, Appetizing, Sterilized).

ØGet pelleting capacity as required.

Ø Control dust quantity and prevent strange matter.

ØLife-time extension of feed. (Reduced moisture of pellet by cooler).

ØRegular physical quality, make customer satisfaction.