IOT&DM

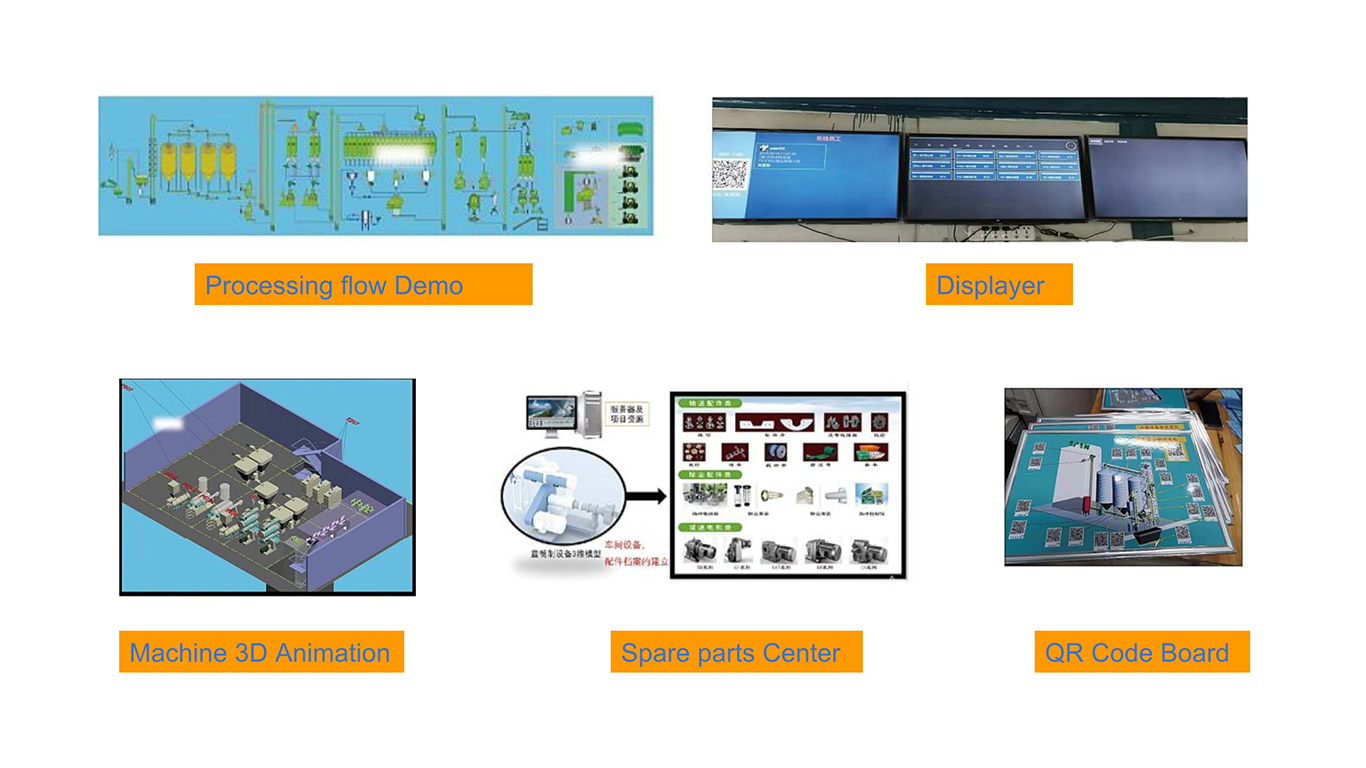

The intelligent factory solution mainly includes the feed factory processing equipment Internet of Things system and equipment DM management system.

The Internet of Things (IOT) system, through automatic processing of device sensors and the Internet, allows users to timely control the operation status of devices through mobile phones, display panels, computers and other terminals, and obtain data reports, chart analysis, etc. to improve efficiency and reduce costs; The data generated is accurate, and various reports are automatically generated, which can be used without manual input.

Fuctional of IOT

ØFeedback variety switching time.

Ø Feedback whether the main engine is idling.

Ø Feedback whether the equipment is started safely.

ØFeedback the production efficiency of the host.

ØFeedback whether the host meets the process requirements.

DM equipment management system is a product of lean equipment management. The system is a preventive management system. It establishes a resource platform through simulation software, visualization software, patrol map, data of each dimension of the workshop, IOT interface, and operation habits of each post, to provide various data resource support for equipment maintenance and production management. The system can greatly improve the maintenance efficiency, including improving the work efficiency of employees, reducing the unexpected downtime, quickly recovering production, reducing the cost of accessories, extending the service life of equipment, eliminating process bottlenecks, etc. The system has rich functions and is equipped with nearly 50 functional modules.

Function of DM

For workers:

ØMore convenient access to equipment accessories, equipment archives and other data.

ØThe equipment maintenance report and the use of accessories report are very convenient, which greatly reduces the workload.

ØThe daily maintenance of equipment only needs to be carried out according to the system plan and reminder, which greatly reduces the accidental failure of equipment and avoids overtime repair to the greatest extent.

For the company:

ØImprove staff efficiency.

ØReduce unexpected downtime.

ØSave the use cost of accessories.

ØReduce the time to restore production.

ØExtend the service life of the equipment.

ØThe equipment status has been improved.

ØAll staff can participate in equipment management.

ØGreatly reduce production safety problems.

ØGroup customers can share parts information, personnel information, etc.